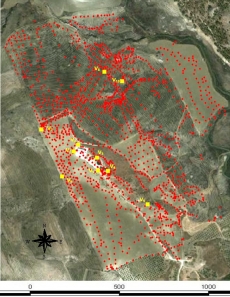

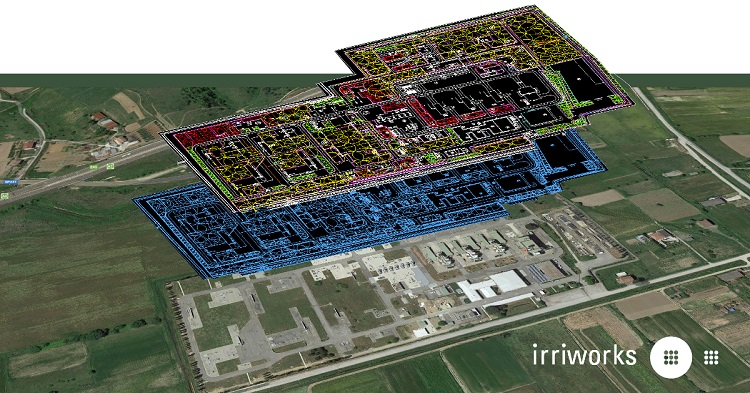

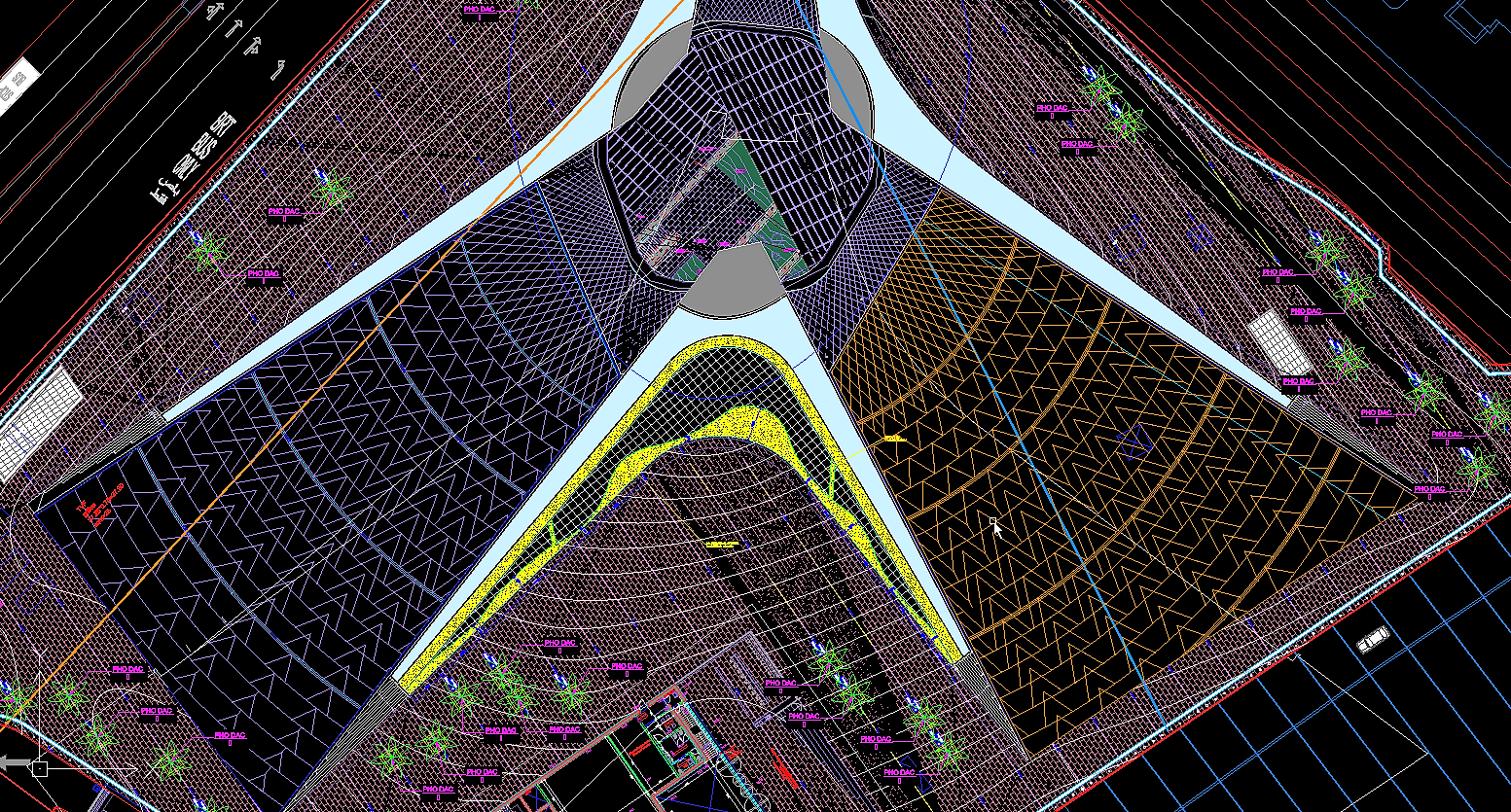

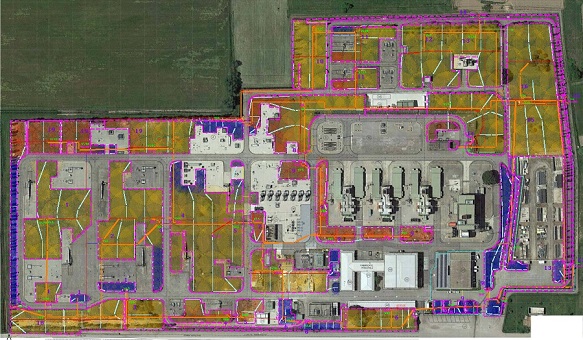

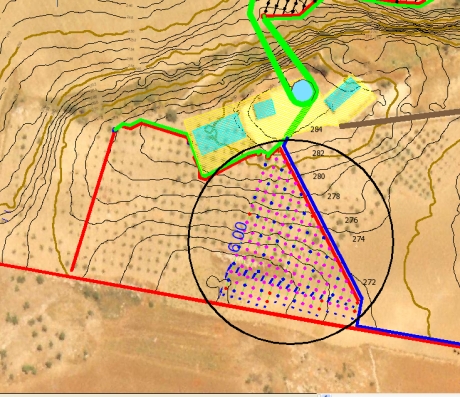

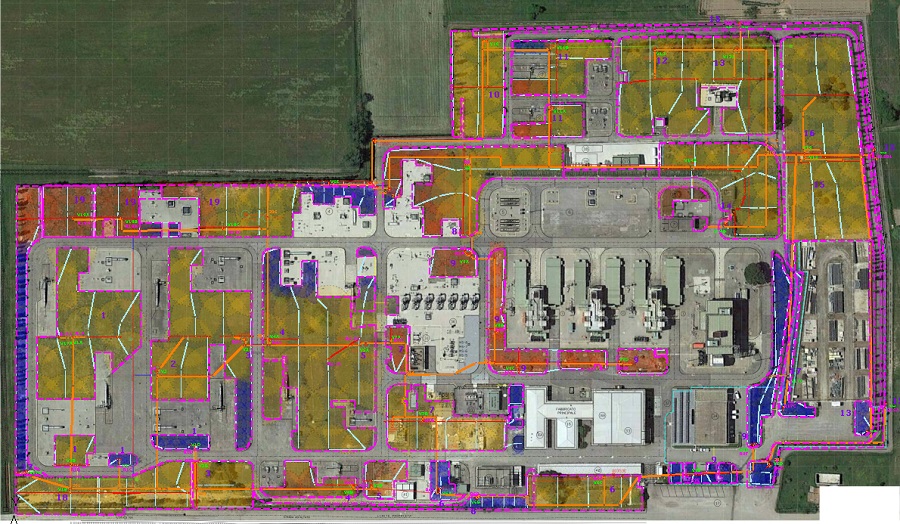

The project involved the irrigation system for green areas within the SNAM plant at the Tarsia town.

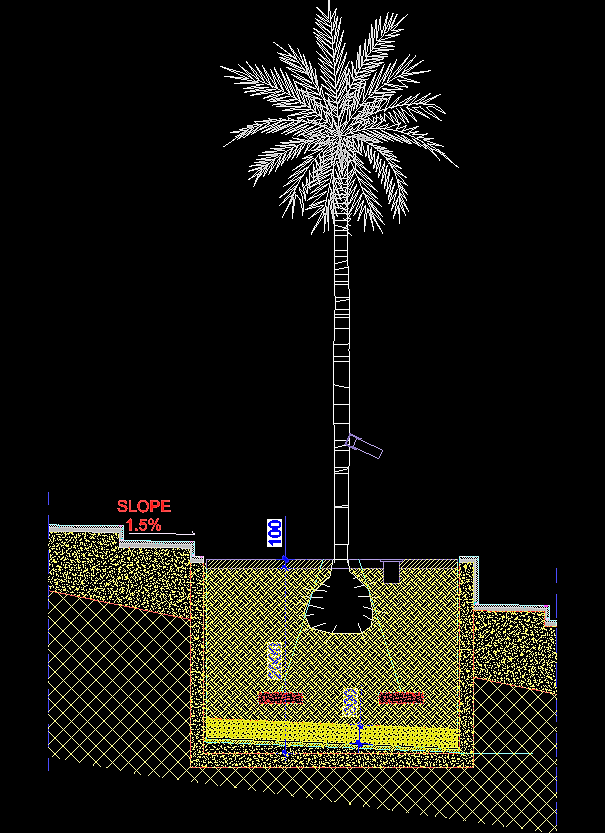

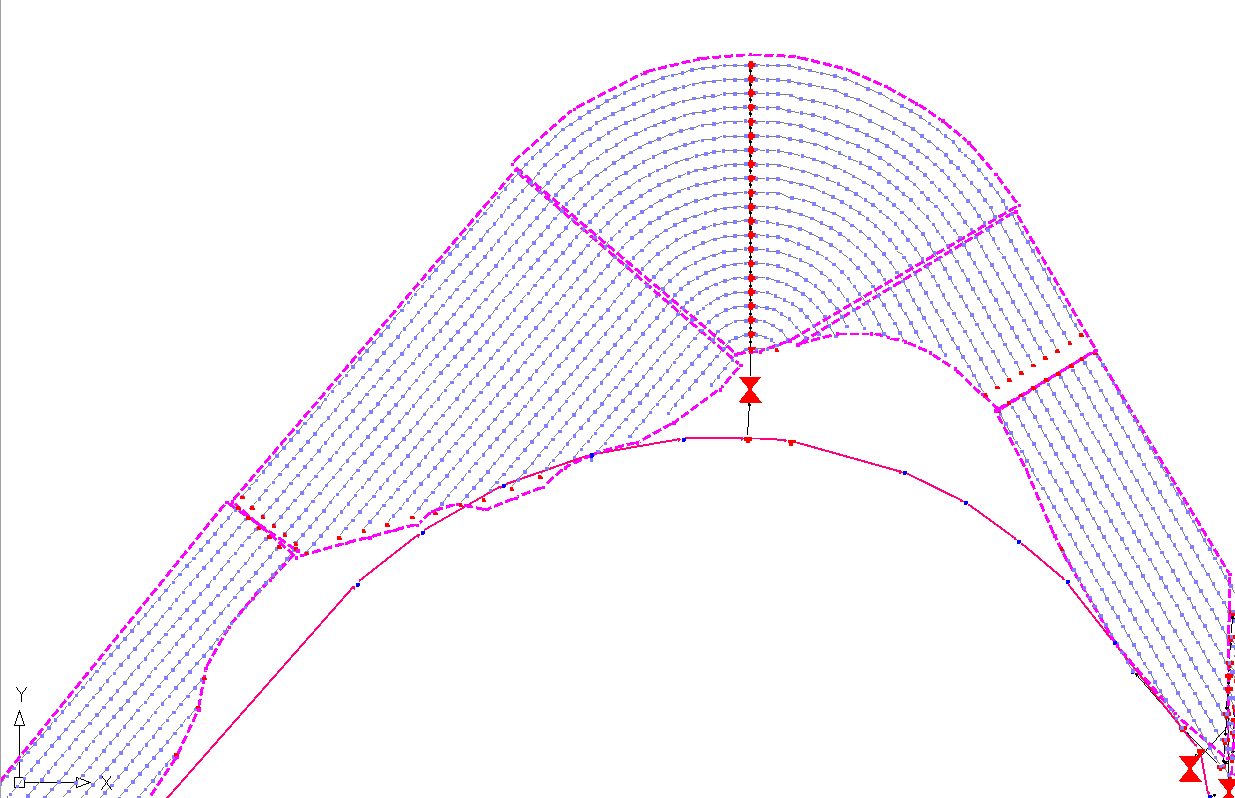

The total area is about 12 hectares and is composed of green lawn beds. The terrain is purely flat. Through a well the water is collected in an accumulation tank that hydraulically separates the constant flow coming from the well and the irrigation system that requires higher flow rates and shorter durations. The pump that feeds the irrigation system from the accumulation tank has been sized for the different shifts so as not to exceed the volume of compensation.

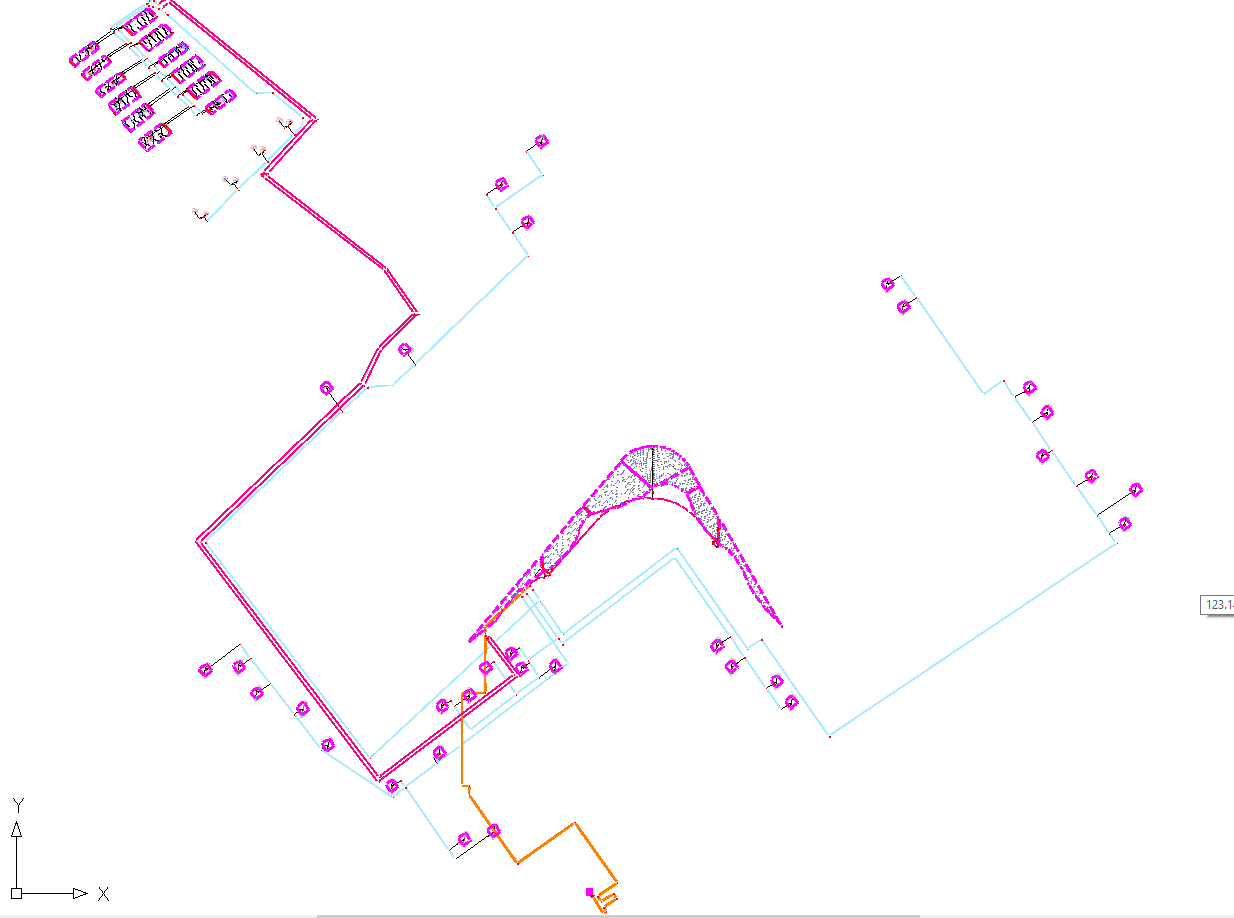

The plant is composed of more than 3000 m of DN90 main pipelines and problems of different crossings for existing works have been tackled. Several sectioning solenoid valves have been inserted so as to divide the main network and command which sections to engage and which to exclude.

|  |

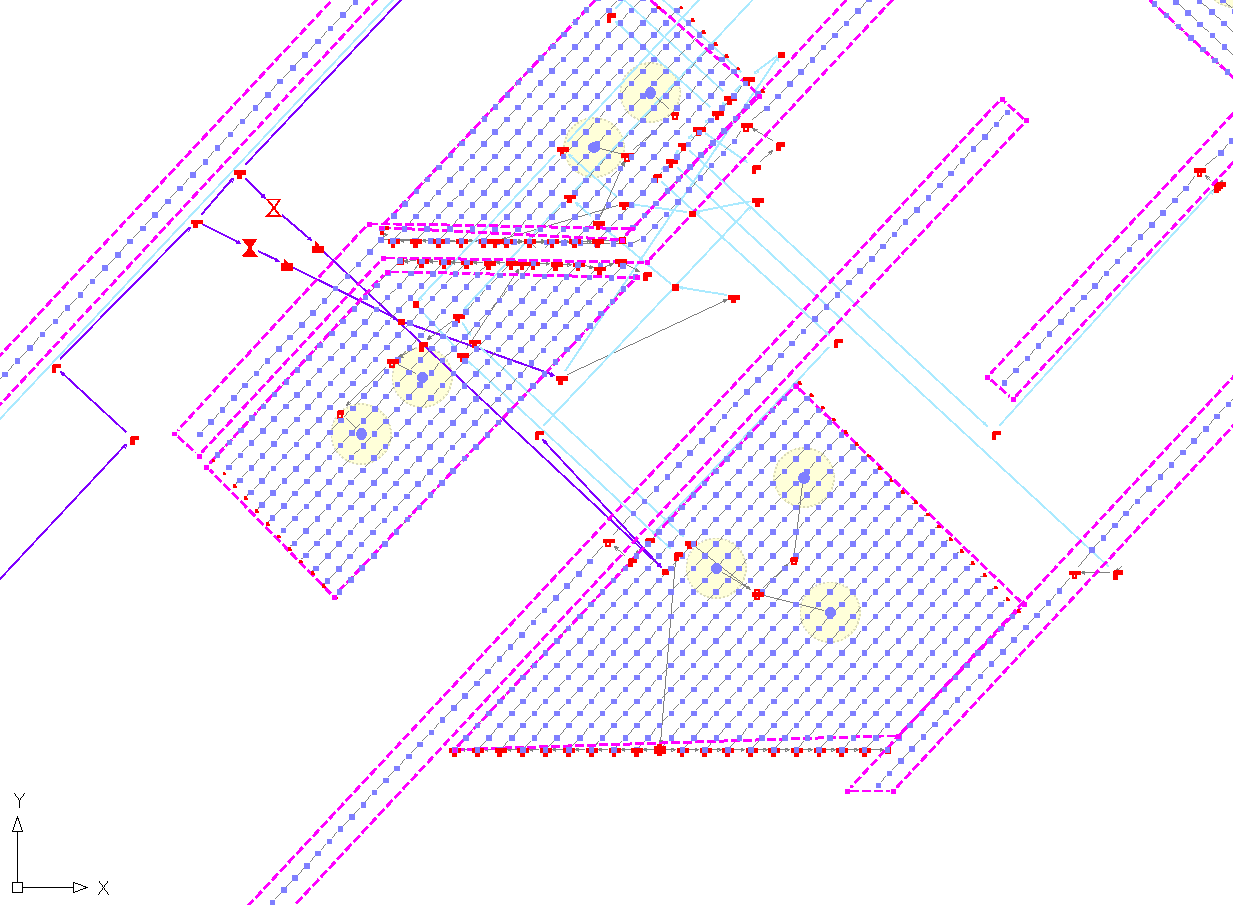

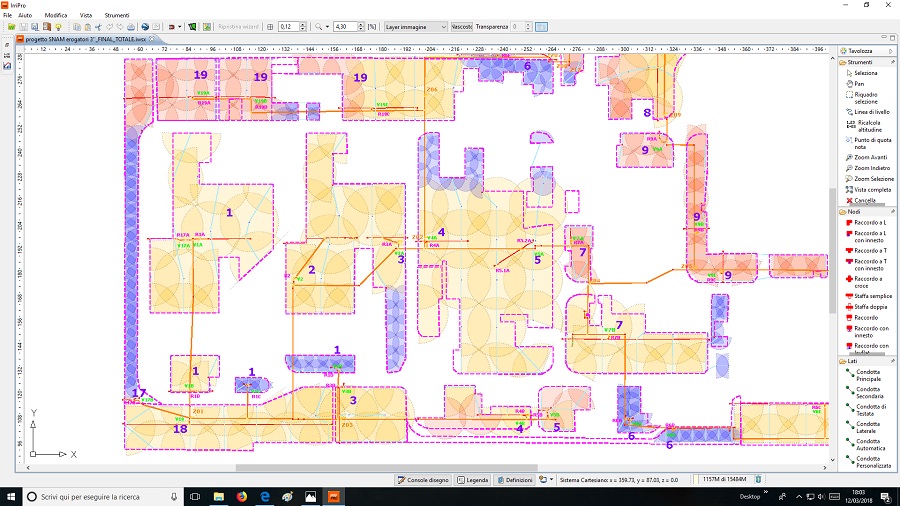

In order to manage the 19 shifts, made up of groups of sectors chosen to balance the flow rate around a set average value in the various shifts, 56 solenoid valves and two control units have been provided to control the valves and the pump in two groups.

The control units can be managed remotely.

The timing of the shifts was drawn up as to:

- have a similar flow for each turn

- cover irrigation within a day

- verify the equivalence between the incoming and the outgoing volume from the supply tank

- simulate further hydraulic conditions.

The turf of the green areas is irrigated with more than 500 pop-up sprinklers (dynamic and static), while the perimeter part with hedges and shrubs is irrigated with dripping (self-compensating) laterals. The pluviometric overlap of wet circles and the uniformity of distribution was verified.

More than 40 pressure reducers have been inserted to keep the pressure below certain limits in some areas of the system (especially for the drip part which requires less pressure to operate).

In the project, different scenarios were assessed (some discarded due to lack of uniformity, efficiency and balancing of flow rates per shift), and finally chosen the one that at the same time reaches the daily requirement to irrigate the entire surface, has an adequate intensity of rain, an acceptable uniformity and is compatible with the conditions of compensation, volume and flow of the source.

Designing an irrigation system is not just about drawing but also perform an hydraulic calculation to obtain quantitative results. Without knowing how it behaves (hydraulically) a network, at any point, how do you know which diameter of the pipeline to adopt or which and how many emitters you can feed?

How can you say that a project is well done, not knowing if at any point is dispensed the right amount of water?

The proper project takes into account all the geometrical parameters, physical, topographical (as well as the boundary conditions where the plant will be built) and uses the most advanced engineering methodologies and mathematical formulas to analyze the quality of irrigation.

The third-party software adopt simplified methods to calculate the flow and pressure: typically they design according to the criterion of constant speed in the pipe or strive for minimum cost (economic). In this way we obtain approximate results and the technician is unable to answer the questions: does the water reach all parts of the installation? Is the irrigation system working well? Can The plant guarantee me an acceptable quality for irrigation?

Take for example a plant on an area of 0.6 hectares with about 5000 emitters built on a lot with variable slopes (with laterals that have an average gradient of 2.5% ranging from a minimum value of -5% and maximum +10%).

On following table it shows the consequences if it isn't considered any parameters in the calculation:

| | IrriPro | Other softwares | Maximum error [%] | Comments |

Variable slope | Processing 3D model of the ground for a variable slope, point by point, section by section, pipe by pipe | Inserting a constant slope for all parts of the system | 40% for the value of uniformity50% for the minimum pressure | The error varies according to the order they are presented with the change of slope |

Variables speed | Calculated as a variable in every point | Set as a constant value | - | In general, the water speed varies in lateral pipes between 5m/s and 0 m/s |

Costant Head losses | Calculated assuming Variables the flow rates of each part of pipe and the outgoing flow from each emitter (rigorous formulation of the equation of motion and continuity) | Calculated by taking the equivalent discharge transiting the entire length of the pipeline | 30% of the total head losses | The evolution of pressure due to continuous losses, calculated as the equivalent discharge of service along the pipe, has a constant slope and differently by reality. The calculation of uniformity in this case is not reliable |

Local head losses | Considered using a rigorous formulation depending on the size of the emitter | Not considered or imposed as a constant proportion of the pressure | 50% of the total head losses | The local head losses (due to the presence of emitters) include up to 50% of the total head losses |

Integral calculus of the system | Integral calculus of all processed laterals considering their mutual interaction between each element | Calculation on a single chosen lateral | - | The reliability calculation for a single lateral (the result is then extended to the whole system) depends on the choice of the lateral and the size of the system |

Temperature | Modifiable | Not modifiable | 7-10% of the total pressures | Temperature affects the viscosity and density of water |

In conclusion, the error committed not considering any or all of the components of the calculation may become significant.

In other words, a simple calculation gives no guarantee to the success of a project.

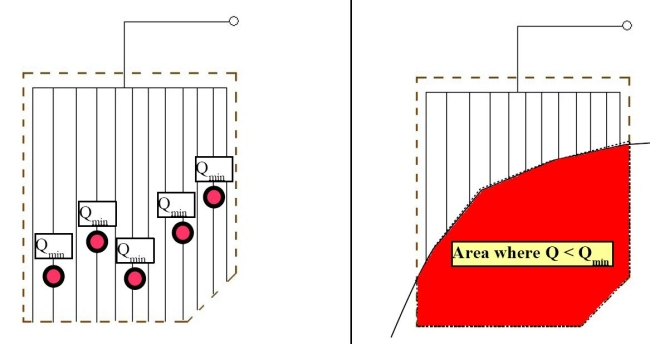

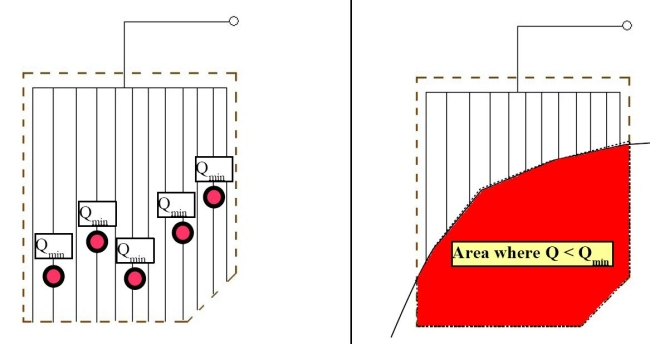

The other software are able to calculate the hydraulic characteristics in few points on the network.

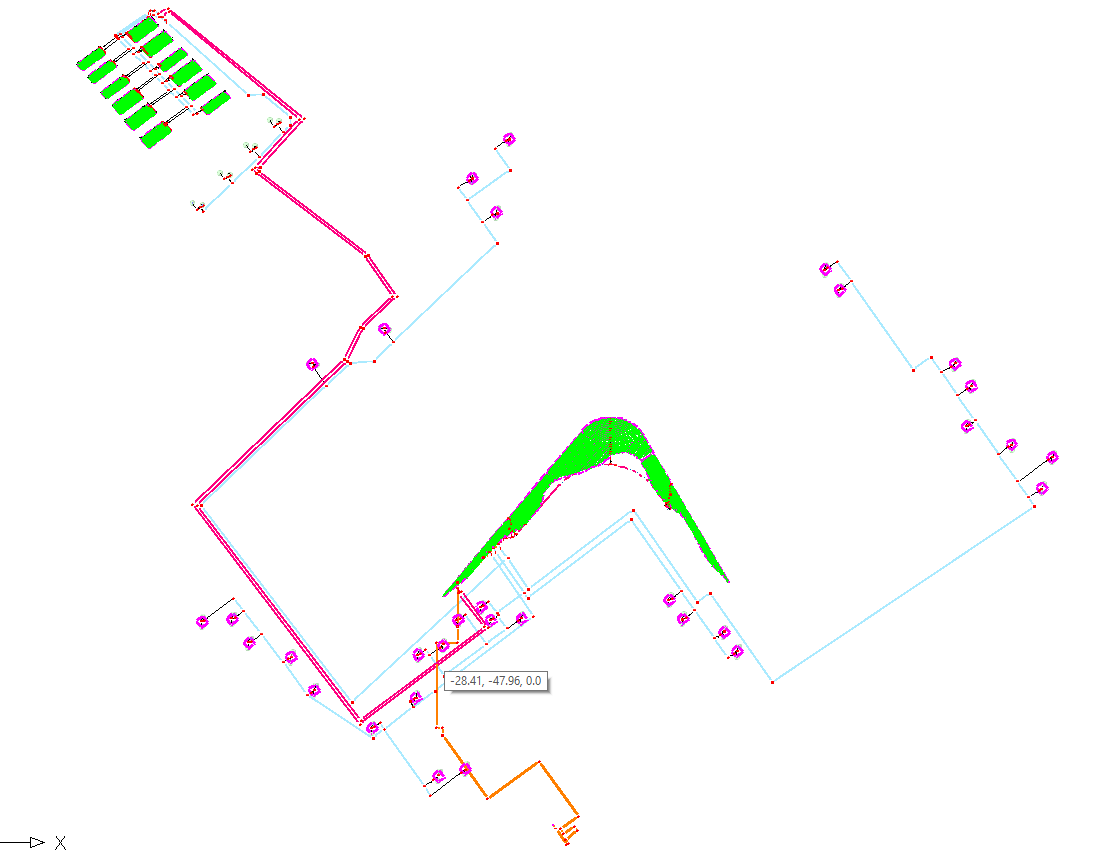

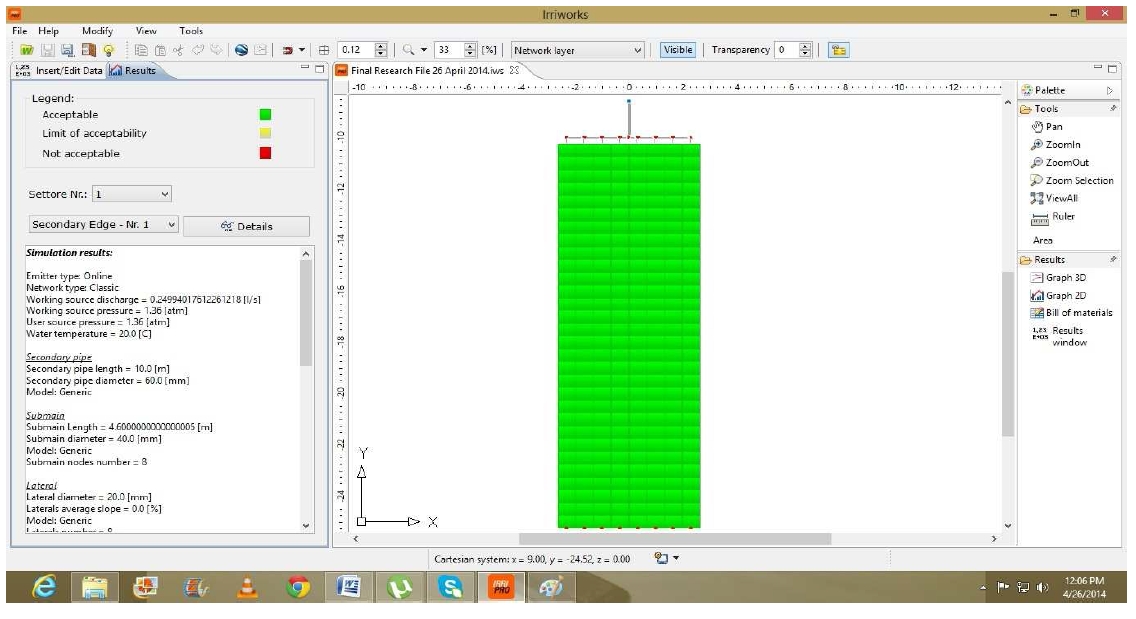

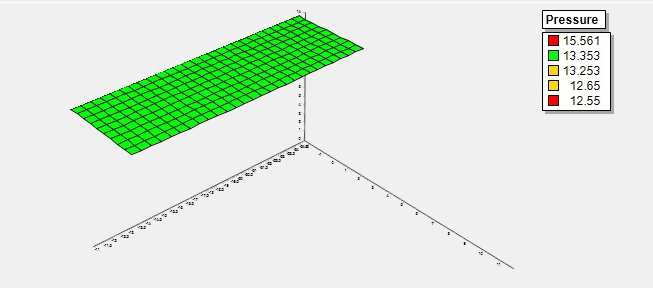

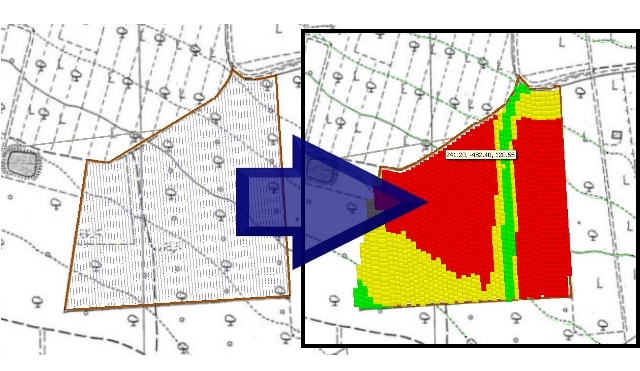

IrriPro, however, allows the designer to know the continuous distribution (not discrete) of the values of pressure and discharge, and therefore know where and how far to correct to improve the project. For example, the thematic map of IrriPro, through different colors for different scales of flow rate and pressure, allows the designer to know how serious and extensive the negative condition is and fix all the points where the water supply is in deficit.

Other software IrriPro

| In this case, how extensive is the area where the designer must adjust the project to improve the conditions? | The overview is complete and, point by point, the designer knows where to intervene |

IrriPro is the only

IrriPro is the only

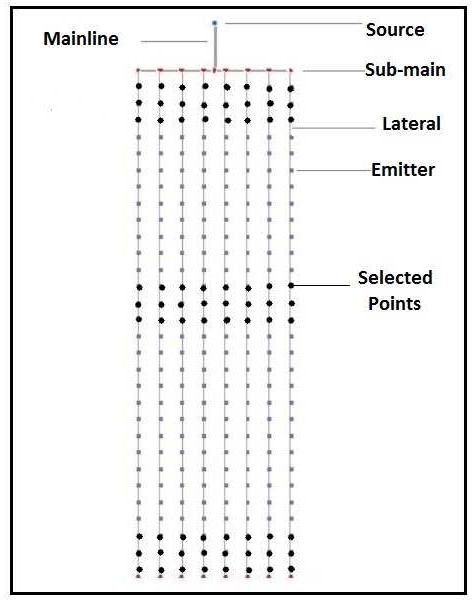

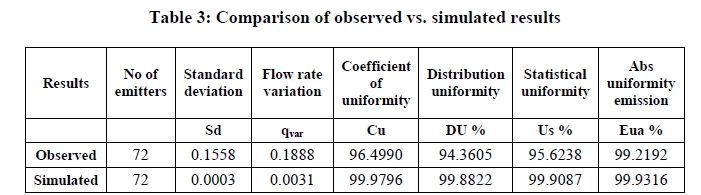

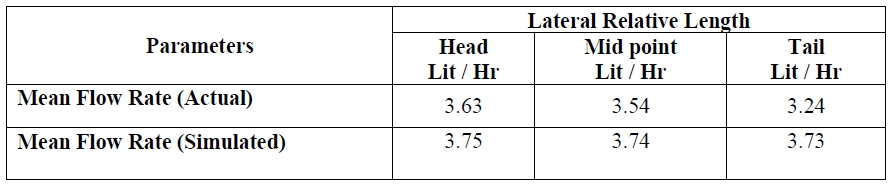

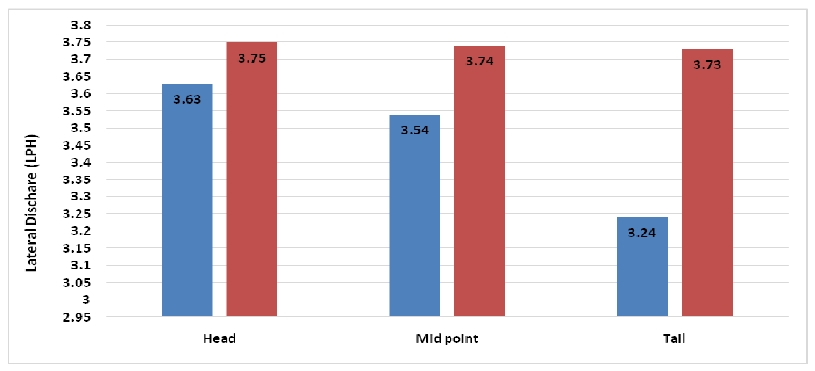

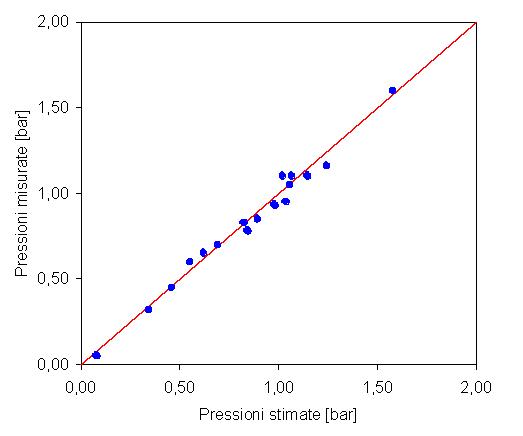

Hydraulic estimation of drip irrigation system was based on a method defined by the ASAE (1999). Three emitters on a lateral were selected at the head, midpoint and tail-end and discharges were measured on them.

Hydraulic estimation of drip irrigation system was based on a method defined by the ASAE (1999). Three emitters on a lateral were selected at the head, midpoint and tail-end and discharges were measured on them. IRRIPRO has the diverse quality to calculate and design many other hydraulic parameters. It is a helping tool for water resource engineers in designing, testing, analyzing any other alternative design on precision and economical parameters.

IRRIPRO has the diverse quality to calculate and design many other hydraulic parameters. It is a helping tool for water resource engineers in designing, testing, analyzing any other alternative design on precision and economical parameters.  The comparative study revealed that the drip irrigation achieved high CU and DU which imply that the existing drip irrigation system was designed on the basis of proper scaling and dimensions. The CU on average basis for the system was found to be 96.4990% (observed) and 99.9796% (simulated) respectively. Similarly, the DU on average basis for the system was found to be 94.3605% (observed) and 99.8822% (simulated) respectively. EUa of the system using pressure compensated type emitters with the length of laterals 16 meters with an average observed and simulated value was found 99.2192% and 99.99316% respectively.

The comparative study revealed that the drip irrigation achieved high CU and DU which imply that the existing drip irrigation system was designed on the basis of proper scaling and dimensions. The CU on average basis for the system was found to be 96.4990% (observed) and 99.9796% (simulated) respectively. Similarly, the DU on average basis for the system was found to be 94.3605% (observed) and 99.8822% (simulated) respectively. EUa of the system using pressure compensated type emitters with the length of laterals 16 meters with an average observed and simulated value was found 99.2192% and 99.99316% respectively.

The plant is composed of more than 3000 m of DN90 main pipelines and problems of different crossings for existing works have been tackled. Several sectioning solenoid valves have been inserted so as to divide the main network and command which sections to engage and which to exclude.

The plant is composed of more than 3000 m of DN90 main pipelines and problems of different crossings for existing works have been tackled. Several sectioning solenoid valves have been inserted so as to divide the main network and command which sections to engage and which to exclude.

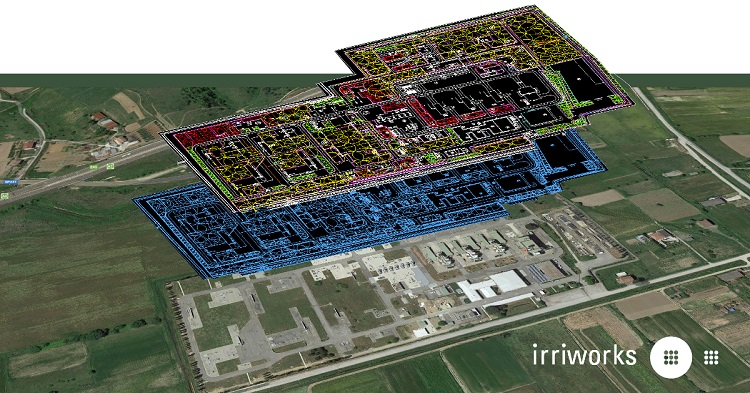

In IrriPro the elements of a

In IrriPro the elements of a  Thanks to IrriPro's innovative technology, which has achieved some

Thanks to IrriPro's innovative technology, which has achieved some